Vital Tips for Effective Welding Inspection Madison Providers

Vital Tips for Effective Welding Inspection Madison Providers

Blog Article

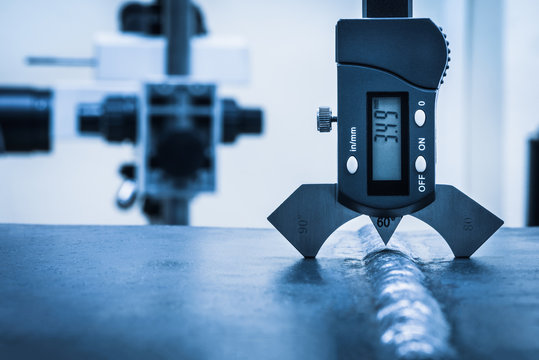

Checking Out Advanced Equipment and Approaches for Accurate Welding Assessment

In the realm of welding inspection, the pursuit of accuracy and dependability is extremely important, stimulating the advancement of cutting-edge tools and techniques. Laser scanning technologies and automated evaluation systems, equipped with man-made knowledge, are redefining the landscape by minimizing human error and improving safety steps.

Ultrasonic Checking Technologies

Ultrasonic testing innovations regularly represent the center of advancements in welding evaluation innovations. These innovations have actually considerably boosted the ability to spot and evaluate discontinuities within welded structures, guaranteeing enhanced stability and security.

Additionally, innovations in software application formulas for information analysis have actually boosted the accuracy of defect discovery and sizing. Automated ultrasonic testing systems now offer high-resolution imaging, making it possible for comprehensive assessments of weld top quality. These systems are usually integrated with advanced visualization tools, which help with the analysis of outcomes.

Radiographic Assessment Strategies

While ultrasonic screening advancements have actually set a high criterion in non-destructive evaluation, radiographic assessment techniques proceed to play an important function in welding evaluation by providing unique insights right into material integrity. Radiographic testing (RT) utilizes using X-rays or gamma rays to pass through products, producing a radiograph that visually represents the internal framework of a weld. This imaging ability is vital for identifying subsurface problems such as porosity, inclusions, and splits that might not show up with surface inspections.

The process involves putting a radiation source on one side of the weld and a detector on the opposite side. Variations in material density and density impact the attenuation of the rays, producing a different image that exactly marks problems. RT is especially beneficial for evaluating intricate geometries and thick areas where other methods might fail.

Regardless of its efficiency, radiographic examination has to be carried out with stringent adherence to safety protocols because of the unsafe nature of ionizing radiation. Furthermore, the analysis of radiographs calls for competent workers, as the top quality of the evaluation straight influences the dependability of the inspection. As a result, recurring advancements in digital radiography are boosting image clearness and analysis effectiveness, enhancing RT's vital function in ensuring weld high quality.

Laser Scanning Advances

Embracing laser scanning innovation in welding evaluation has actually reinvented the analysis of weld high quality and stability. Unlike conventional examination strategies, laser scanning supplies rapid data purchase, dramatically enhancing the efficiency and precision of weld analyses.

Laser scanning breakthroughs have actually resulted in substantial improvements in discovering and characterizing surface problems such as porosity, lack of fusion, and undercuts. The high-resolution information makes it possible for assessors to carry out detailed evaluations, ensuring that welds fulfill rigid industry requirements. This approach sustains the growth of electronic documents, helping with long-lasting high quality guarantee and traceability.

Furthermore, laser scanning modern technology incorporates seamlessly with software program solutions created for automated defect discovery and assessment. The resultant data can be quickly shared and reviewed, advertising collaborative decision-making procedures. As markets remain to require higher standards for weld high quality, laser scanning continues to be at the center, offering unequaled accuracy and performance in welding inspection.

Automated Evaluation Solutions

Automated examination systems supply the advantage of uniformity, getting rid of human mistake and subjectivity from the assessment process. They are made to operate in different settings, from manufacturing floors to remote area sites, guaranteeing extensive protection. Welding Inspection Madison. These systems read more can be programmed to comply with particular welding requirements and standards, giving detailed records and paperwork for top quality control objectives

In addition, the integration of cloud-based systems helps with the storage and analysis of large quantities of evaluation information. This enables pattern analysis my latest blog post and anticipating maintenance, permitting suppliers to attend to potential concerns before they intensify. The fostering of automated inspection systems is a crucial action in the direction of enhancing the reliability and effectiveness of welding processes in commercial applications.

Enhancing Safety and Efficiency

A significant aspect of improving safety and security and efficiency in welding inspection depends on the combination of ingenious innovations that enhance operations and mitigate risks. The adoption of innovative non-destructive screening (NDT) approaches, such as ultrasonic testing, phased range ultrasonic screening (PAUT), and radiographic testing, plays a pivotal function in ensuring architectural honesty without jeopardizing the safety of the workers involved. These techniques enable for detailed assessments with very little downtime, lowering potential threats connected with conventional techniques.

Moreover, the implementation of real-time data analytics and maker learning formulas has changed the means assessment data is interpreted. By using predictive analytics, possible flaws can be recognized before they show up into essential failures, guaranteeing prompt treatments and upkeep. This proactive strategy substantially improves functional performance and safety and security in welding processes.

Additionally, remote inspection innovations, including drones and robot crawlers equipped with high-resolution electronic cameras, enable inspectors that site to examine hard-to-reach areas without revealing them to hazardous problems. This not only enhances examination accuracy however additionally decreases human risk. By leveraging these advanced devices and techniques, sectors can accomplish higher safety requirements and operational effectiveness, ultimately causing even more lasting and trusted welding inspection practices.

Final Thought

The assimilation of sophisticated devices and approaches in welding assessment significantly enhances defect discovery and ensures architectural honesty. Welding Inspection Madison. Innovations such as phased selection ultrasonic screening, electronic radiography, and laser scanning enhance flaw characterization, while automated assessment systems and AI reduce human error. Remote technologies facilitate safe assessments in harmful settings, promoting an aggressive upkeep approach. These improvements not only increase inspection effectiveness but also contribute to improved safety and security and quality control in commercial welding applications.

Ultrasonic testing innovations regularly represent the leading edge of advancements in welding evaluation technologies.While ultrasonic testing developments have set a high criterion in non-destructive examination, radiographic inspection methods continue to play an essential function in welding inspection by offering special understandings into product stability.Welcoming laser scanning modern technology in welding assessment has actually revolutionized the analysis of weld top quality and integrity. As industries proceed to require higher standards for weld high quality, laser scanning continues to be at the forefront, offering unrivaled accuracy and efficiency in welding evaluation.

Automated evaluation systems supply the advantage of consistency, removing human mistake and subjectivity from the assessment process.

Report this page